We may not have the course you’re looking for. If you enquire or give us a call on +1 7204454674 and speak to our training experts, we may still be able to help with your training requirements.

Training Outcomes Within Your Budget!

We ensure quality, budget-alignment, and timely delivery by our expert instructors.

.png)

The NEBOSH Open Book Exam is a unique approach to assessing knowledge and understanding of health and safety concepts. NEBOSH Question Paper offers candidates the flexibility to complete the exam remotely while maintaining the integrity of the assessment process.

Being an open-book exam, the questions are scenario-based, requiring you to use your unique thought process and have strong fundamentals about the topics. In this blog post, we will explore the pattern and result process of the NEBOSH Open Book Exam and provide you with some sample questions to help you prepare.

Table of Contents

1) NEBOSH open book Exam pattern and result process

2) Sample NEBOSH Question Paper

a) Scenario 1

b) Scenario 2

3) Conclusion

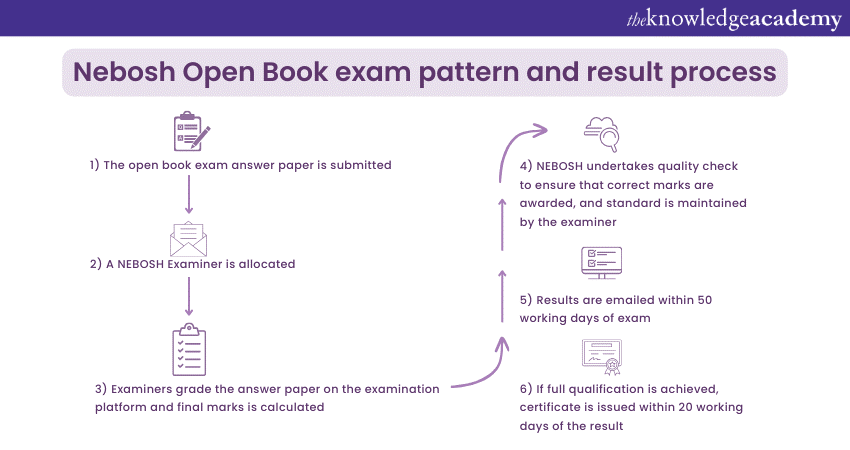

NEBOSH open book exam pattern and result process

NEBOSH has done away with the traditional invigilated exam pattern and how it conducts an open book exam. The exam is 24 hours long, and you are presented with a realistic scenario for completing some tasks. This format of examination applies to all certificates and diplomas.

During the examination, you will have access to all resources you might need, but you need to present answers with respect to the given scenario. There is no "perfect" answer in this case. You need to apply your experience and your learnings from the course. The process for results takes some time, but it is conducted to make sure that candidates get the most authentic results for their effort.

Enhance your career in health and safety and get certified with NEBOSH National General Certificate in Occupational Health and Safety training course.

Sample NEBOSH Question Paper

The given tasks or questions carry certain marks, usually in the range of 10-15 marks.

Scenario 1

You are a health and safety manager working for a construction company called BuildSafe Contractors. The company specialises in residential and commercial building projects and has recently started working on a high-rise construction project in a busy city centre. As the health and safety manager, you are responsible for ensuring that all construction activities are conducted safely and comply with relevant regulations and best practices.

There are some main concerns raised by project stakeholders, workers, and local authorities concerning working at a height, electrical safety, site access and more.

The construction project involves significant work at height, including installing façade elements, window glazing, and exterior painting. Recently, a new young worker at the construction site injured himself by falling from a short height while working on a ladder. Although the worker didn't sustain any major injury, the incident wasn't looked into and was not taken seriously by the site supervisor or upper management.

The construction site requires extensive excavations for the foundation and underground services. The project also involves installing electrical systems, wiring, and lighting fixtures. Additionally, adequate grounding, circuit protection, and lockout/tagout measures should be in place to prevent electrical accidents.

The construction site may use hazardous substances such as adhesives, solvents, paints, and concrete additives. There is a need to implement proper storage, handling, and disposal procedures for these substances. Adequate ventilation, personal protective equipment (PPE), and worker training are essential to minimise the risks associated with hazardous substances.

Due to the site's location in a busy city centre, there are challenges related to site access and egress. Pedestrian safety, traffic management, and coordination with local authorities are crucial to ensure the safe movement of workers, visitors, and construction vehicles in and around the site.

Task 1: Basics of health and safety

You need to identify and assess the potential health and safety hazards associated with the project and then develop a plan to control these hazards to ensure a safe working environment.

Task 2: Culture of safety in the workplace

Based on the scenario only, comment on the health and safety culture on site.

Task 3: Working from a height

When questioned, the young worker said they knew the ladder was unsafe for the roof guttering removal task because they had recently completed their height safety training. What safety considerations should the worker have made regarding the suitability of the ladder for the job? Do you think workers need more safety training?

Task 4: Electrical work

What are some of the hazards while carrying out electrical work? According to the nature of work, mention some hazards and existing controls in place. Based on the associated risk, mention what additional controls you would have in place.

Task 5: Perform a comprehensive risk assessment

a) Analyse each phase of the construction project and identify potential hazards and risks.

b) Identify and assess the potential risks and then prioritise them based on their likelihood of occurrence and the potential impact of their occurrence.

c) Consider the control hierarchy to develop appropriate measures for each identified risk.

Note: Remember to provide detailed explanations and justifications for your proposed control measures, referring to relevant legislation, standards, and best practices. Ensure that your recommendations are practical, feasible, and specific to the scenario presented.

Scenario 2

You are a health and safety officer working for a large pharmaceutical company. The company specialises in the production of prescription medications and operates several manufacturing facilities across different locations. Recently there have been growing concerns regarding the potential risks of implementing a new chemical process within one of our manufacturing plants.

Your task is to conduct a comprehensive risk assessment of the new chemical process and develop effective control measures for the safety of employees working with the chemicals. The process involves handling and mixing highly reactive substances used in synthesising a critical drug compound. The manufacturing plant has a dedicated area for this process, including specialised equipment and ventilation systems.

The main concerns raised by employees and management include the following:

a) Chemical hazards: The new chemical process involves working with highly reactive substances that pose risks such as fire, explosion, and toxic gas release. The employees involved in the process must be protected from exposure to these hazards.

b) Personal protective equipment (PPE): Employees have expressed concerns about the adequacy of PPE provided for working with the chemicals. They feel the current PPE may need to provide more protection against the identified hazards.

c)Emergency response: If there is an accident regarding the chemical spill, release, or fire, there is a need for clear emergency response procedures, including evacuation plans, alarm systems, and spill containment measures. Workers must be trained on how to respond effectively to emergencies and the location of emergency equipment.

d) Training and competence: Some employees have recently been assigned to the new chemical process and require training on the specific hazards, safe handling procedures, and emergency response protocols. Ensuring that all employees involved in the process are trained properly and are competent to perform their tasks safely is essential.

e) Process containment: The process involves using containment systems to isolate the chemical process from the environment. The effectiveness of these containment systems needs to be assessed, and any necessary improvements or modifications should be implemented.

As a health and safety office, you must conduct a detailed Nebosh risk assessment of the new chemical process and develop a comprehensive health and safety plan to address the identified concerns. You should consider relevant legislation, industry guidelines, and best practices while developing your recommendations.

Task 1: Chemical process assessment

a) Conduct a thorough assessment of the new chemical process, including the substances used, their properties, and potential hazards.

b) Identify potential risks such as fire, explosion, toxic gas release, and chemical reactions.

c) Evaluate the adequacy of current control measures and determine areas for improvement.

Task 2: Process containment evaluation

The separate process containment zone is being used to isolate the new chemical process. Assess the effectiveness of the current containment systems for preventing the release of hazardous substances and identify any areas for improvement.

Task 3: Emergency response planning

a) Develop comprehensive emergency response procedures for potential incidents related to the new chemical process.

b) Outline evacuation plans, assembly points, and communication protocols.

c) Ensure the availability and proper placement of emergency equipment like fire extinguishers, spill kits, and emergency showers.

Task 4: Safety of people in the event of a fire

Based on the scenario, what control measures could help evacuate workers in a fire?

Task 5: Risk assessment

a) Perform a comprehensive risk assessment of the new chemical process, considering all potential hazards and associated consequences.

b) Assess the likelihood and severity of each identified risk to prioritise control measures.

c) Apply the hierarchy of controls to develop appropriate control strategies for each risk.

Conclusion

NEBOSH Question Papers can be tricky as all the questions are scenario-based, but access to resources during the exam can help you. For the NEBOSH exams, it is essential to grasp the fundamental concepts and knowledge. Make sure you use your understanding of the concepts, experience and what you learned during the course study.

Start your journey to a rewarding career in health and safety with the NEBOSH International General Certificate In Occupational Health And Safety Training course.

Frequently Asked Questions

The NEBOSH exam typically takes around 4-5 hours to complete, with some specific exams like the Health and Safety Management for Construction Certificate taking 10-14 hours.

You can resit a failed NEBOSH unit as long as you do so within five years of your first successful unit being issued.

The Knowledge Academy takes global learning to new heights, offering over 30,000 online courses across 490+ locations in 220 countries. This expansive reach ensures accessibility and convenience for learners worldwide.

Alongside our diverse Online Course Catalogue, encompassing 17 major categories, we go the extra mile by providing a plethora of free educational Online Resources like News updates, Blogs, videos, webinars, and interview questions. Tailoring learning experiences further, professionals can maximise value with customisable Course Bundles of TKA.

The Knowledge Academy’s Knowledge Pass, a prepaid voucher, adds another layer of flexibility, allowing course bookings over a 12-month period. Join us on a journey where education knows no bounds.

The Knowledge Academy offers various NEBOSH Courses, including the NEBOSH Award In Health and Safety at Work Course, NEBOSH Working with Wellbeing Training and NEBOSH HSE Award in Managing Risks and Risk Assessment at Work Training. These courses cater to different skill levels, providing comprehensive insights into Importance of Safety at Workplace.

Our Health & Safety Blogs cover a range of topics related to health and safety, offering valuable resources, best practices, and industry insights. Whether you are a beginner or looking to advance your mitigate risk skills, The Knowledge Academy's diverse courses and informative blogs have got you covered.

Upcoming Health & Safety Resources Batches & Dates

Date

NEBOSH Award in Health and Safety at Work

NEBOSH Award in Health and Safety at Work

Mon 23rd Sep 2024

Mon 9th Dec 2024

Mon 16th Dec 2024

Mon 13th Jan 2025

Mon 10th Mar 2025

Mon 19th May 2025

Mon 21st Jul 2025

Mon 15th Sep 2025

Mon 17th Nov 2025

Mon 15th Dec 2025

Top Rated Course

Top Rated Course.png)

If you wish to make any changes to your course, please

If you wish to make any changes to your course, please